Nissan Chemicals NanoActiv® technology has proven to be a game changer for increased oil production…

November 2023 BOE Report

Innovative nano technology demonstrates significant increased hydrocarbon recoveries while lowering CAPEX/ OPEX cost and GHG emissions.

Recent long term well production data demonstrates that negatively charged silica dioxide nano particles are the “go to” technology for the oil and gas industry when it comes to increased production and increased recovery factors. These nano particles, when mixed with a surfactant and pumped during fracking operations, have allowed Operators to realize significant increases in oil recovery over 12-24 months, relative to wells where conventional or “nano liquid” surfactants were pumped.

The oil and gas industry leader in nano particle technology is Nissan Chemical America Corporation (NCAC). Their line of nanoActiv® products is based on a silica dioxide nano particle coated with proprietary technology. Unlike other nano particles, that may form an aggregate when in a static reservoir environment, the nanoActiv® particles continue to repel each other due to their negative charge. These nano particles are smaller than a red blood cell and once in the reservoir they migrate outwards, (process called Brownian Motion), via the tight formation matrix, disjointing and fragmenting oil molecules from the rockface thus allowing less restricted oil flow through the matrix and towards producing fractures.

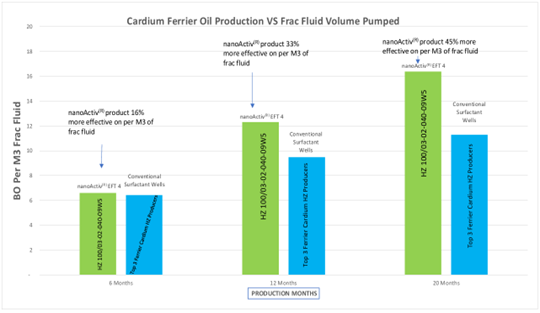

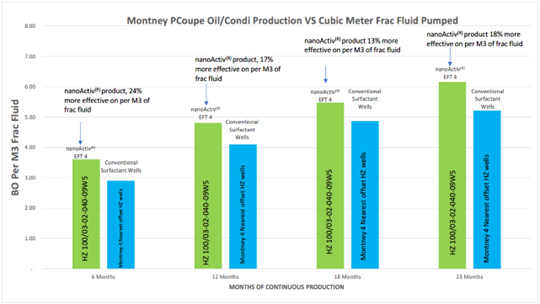

Figures 1 and 2 are a comparison of oil recovery volumes per cubic meter (M3) of frack fluid pumped. The green bar demonstrates oil recovered with nanoActiv® EFT 4 added to the frack and the blue bar demonstrates oil recovered with a surfactant only added to the frack. As indicated in both Figure 1 and 2 the recovered oil volumes after 12-24 months are anywhere from 20-45% higher when the nanoActiv® EFT 4 is added to the frack. Based on a 12 and 24 month production cycle we can assume that the 30-36 month production forecast will see the ratio continue to increase as higher oil volumes are recovered from nanoActiv® wells versus standalone surfactant wells.

A 20-45% increase in oil production per cubic meter of frack fluid pumped is a game changer for our industry. Operators can now realize a higher oil recovery factor without the requirement for larger volume fracks. This not only reduces CAPEX cost but also means lower freshwater requirements to obtain higher overall production volumes and therefore lower OPEX cost per BOE produced.

Western Petroleum Management (WPM) is the exclusive Canadian provider of Nissan Chemical America Corporation line of nanoActiv® products. Mark Schumlick, VP Business Development at WPM stated that it’s taken several years to convince the industry of the relation between increased oil recoveries and NCAC proprietary nano silica dioxide particles. “The investment community especially, was focused on flush production volumes and achieving payout on capital in the first 6-12 months and therefore missed the opportunity nano technology could add to help curtail production decline and increase recoverable reserves over the following months and years”.

Schumlick said, “WPM is continuing to innovate and has recently developed a new enhanced hybrid blend for the Canadian market which we are currently testing at local oil and gas laboratory facilities in the Calgary area”. The enhanced hybrid surfactant has incorporated both a liquid nano emulsion (10-30nm) and Nissan’s proprietary silica dioxide nano particle. The idea behind this hybrid surfactant is to allow nano emulsion droplets to migrate into the near fractured formation matrix during fracking operations and the nano particles (through Brownian Motion) to migrate deep into the formation matrix post frack. The combined effects of both these nano technologies can improve oil recovery during the flush production cycle, (nano emulsion), and increase oil volumes recovered over the ensuing 12-24 months, (nano particles).

Initial performance results from multiple laboratory tests are very promising and Schumlick expects that upon successful completion of these tests the first field trials, (new well frack), will take place in Q1 or 2 of 2024. “As the timeline to determine field success of this hybrid technology is 12+ months we don’t expect to be publishing data until mid-2025”, Schumlick stated. Companies that want to be kept updated or would like to discuss their upcoming frack, waterflood or re-stim projects and product requirements can contact Mark Schumlick directly.